|

#2143706 - 02/21/07 08:33 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Mar 2003

Posts: 1,507

Ripcord

Member

|

Member

Joined: Mar 2003

Posts: 1,507

Houston, Texas

|

Static, thanks for posting. It appears that you read my post about making F/A-18 panels.

All of this depends on what aircraft you want to do. 80% of the people here are probably building a F-16 (could be wrong, just a guess). Possibly because the sims for that aircraft are so good and the dimensions for those pits/panels are so readily available. So what would be the simplest to start with probably.

I am interested in getting panels done for the FA-18, as you saw. Not a lot of info on that is available. Right now I'm talking to another guy that does great work on F-16 panels, and I'm hoping that project will go somewhere. But that wouldn't stop you from making them as well, just need to gauge the demand. Maybe others would be interested in other panels for other aircraft.

Ripcord

USN/USMC -- when it positively, absolutely has to be blown up overnight.

|

|

#2143973 - 02/22/07 04:23 AM

Re: CNC Machinist - I can make these parts easy.

[Re: GlynD]

Re: CNC Machinist - I can make these parts easy.

[Re: GlynD]

|

Joined: Sep 2006

Posts: 4,353

HitchHikingFlatlander

Senior Member

|

Senior Member

Joined: Sep 2006

Posts: 4,353

California

|

Personally long term my pit is multi purpose so it would be cool to see what custom projects you could offer. I've decided to make all my own stuff as far as panels go but its still great to have another source for this kind of stuff.

I've got a bad feeling about this.....

|

|

#2144460 - 02/22/07 07:13 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Uther]

Re: CNC Machinist - I can make these parts easy.

[Re: Uther]

|

Joined: Mar 2006

Posts: 32

Static

Junior Member

|

Junior Member

Joined: Mar 2006

Posts: 32

Detroit, Michigan

|

Hello all. Well I have been scouring the web for cockpit pictures and/or drawings. I have found an F-16 and an F-22 AutoCAD drawing file ( file extension is .dwg). I can read the F-22 file but the F-16 file locks up my AutoCAD program. Here are 2 links I found that seem very nice. Most of you have probably seen them. http://www.habu2.net/vipers/viperpits/index.htmlAnd this one here has some awesome pics of panels up close. I had to download the jpgs separate from each other. This is where I found the AutoCAD drawing files. I tried to download the F-16 dwg file but still no luck. http://www.habu2.net/vipers/viperpits/index.htmlI have noticed that in most of the pics I have been looking at of panels that the lettering is applied after coating. This means it may be raised off the surface by a very small amount. Engraving the lettering and filling in the Lettering with white paint would mean that dust and other debris may get stuck in them tiny little spaces. So the other route here would be to actually apply the lettering in some other fashion that would hold up to the wear of rubbing your fingers across it over time. Also you will notice in one of the websites i have posted above in this post that that have the actual ttf (true type font) military spec files you see in the actual F-16. I game going to speak with the higher ups in my company about how much it would cost for me to have panel coated with a black hard anodized coating and the actual military font lettering applied. This would be done outside of my company but we send stuff out everyday to be coated so I may be able to get a deal on it. This is the panel picture I will get a quote on. Mind that this is only an estimate as just to see what we are talking about cost wise. For actual military spec coatings. I will get an approximate cost for these 2 panels to be coated and lettered as seen in the pics. Sensor Power & AVTR panels - The file name is "panel -16- .jpg" scroll down about 95% of the webpage http://www.simpits.org/fileproc/showfiles.php and open up the picture "panel -16- .jpg" Very nice panels this guy is showing by the way. Ill check back in with you tomorrow. If possible. Also I have been looking at F-18 panels  Static

|

|

#2144467 - 02/22/07 07:27 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Mar 2006

Posts: 32

Static

Junior Member

|

Junior Member

Joined: Mar 2006

Posts: 32

Detroit, Michigan

|

I just noticed this. I was looking at my brand new handy dandy TrackIR hat attachment. This is a perfect example of an applied coating to metal. Look at it closely you will see a very small crinkle finish in the coating. Mine is black. Another example is my beat up joystick. My X-45 Saitek had a blue coating over the top base plate. This is a blue shade of anodizing. Anodizing is usually .0001" to .001" thick. Not very thick but very durable. Some of you may know this but for those of you that don't theres little info for ya.

|

|

#2144491 - 02/22/07 08:08 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Mar 2003

Posts: 1,507

Ripcord

Member

|

Member

Joined: Mar 2003

Posts: 1,507

Houston, Texas

|

Static, Regarding the F/A-18 panels, please see this thread at frugals. http://forums.frugalsworld.com/vbb/showthread.php?t=44259&goto=newpostAnd note that we have copies of the NATOPS in pdf format. I can send that to you, for E/F version (Superhornet). It has foldouts of all the panel. You just take them down to Kinko and have them blown up exactly 400%. It's not CAD, but maybe it will help -- the guy that might be able to help more on that is Pretzel. He's made his own everything, even a HUD. Just see that thread. Learning a lot from your posts, Static. Glad you are here. Ripcord

USN/USMC -- when it positively, absolutely has to be blown up overnight.

|

|

#2144807 - 02/23/07 05:20 AM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Apr 2002

Posts: 17,733

Joe

Veteran

|

Veteran

Joined: Apr 2002

Posts: 17,733

Bridgewater, NJ

|

Yeah, an actual working MFD with a screen (2 of them, in fact, I think), milspec, for use in military training simulators.

In sims the video from an MFD has to come from a completely different world than the bezel and buttons, so a real MFD is not even that useful. For more useful are to-scale parts (including MFD bezels) that look like the real thing. Acting like the real thing then becomes the responsibiltiy of the home cockpit builder.

Like Ripcord, I am interested in F-18E panels. If the lettering is raised instead of engraved or vice versa, I don't care. I am shooting for something that looks like the real thing, but it doesn't have to stand up to a minute comparison with the real thing.

|

|

#2144916 - 02/23/07 10:30 AM

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

|

Joined: Apr 2004

Posts: 3,942

453Raafspitty

Senior Member

|

Senior Member

Joined: Apr 2004

Posts: 3,942

Australia,Sandstone Point

|

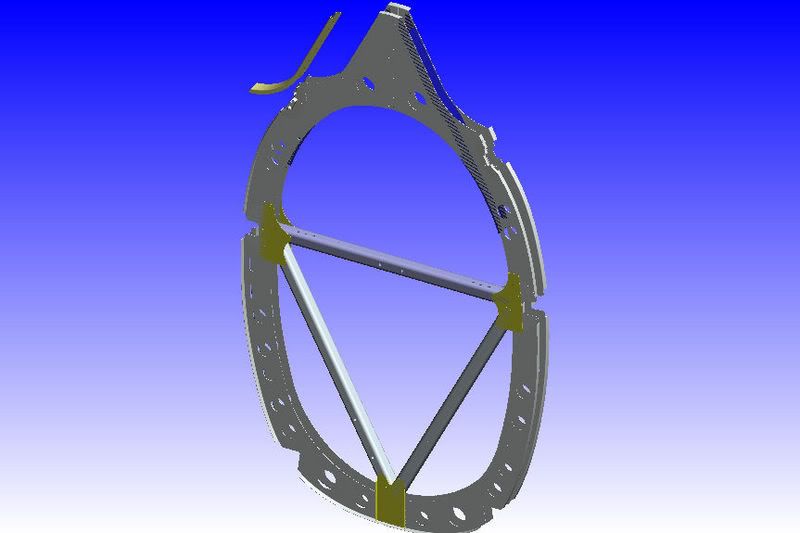

We use 3D Parametric for our project.Olde skool planes rule!!!!What is the maximum depth of your Z axis? IMG] http://i17.photobucket.com/albums/b66/Austiger/Co2Bottlehandle.jpg[/IMG]  We are thinking of going for a cheap small CNC miller/router for small castings etc...It is definately the future...Was talking to a guy today who had restored a Mk XVI Spitfire 20 years ago and he was gobsmacked..Kept on saying,shaking his head "Where was this when I was building my plane?"

|

|

#2145049 - 02/23/07 02:37 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Apr 2002

Posts: 17,733

Joe

Veteran

|

Veteran

Joined: Apr 2002

Posts: 17,733

Bridgewater, NJ

|

Static, These are the same link. Copy/paste error? Can you give me the direct link to that AutoCAD file? I'll try to open it too. I use AutoCAD LT 2004. I took a look at the F-22 cockpit dwg. It's not very detailed. If you want me to use the F-18E NATOPS and draw over it to scale in AutoCAD, let me know.

|

|

#2145119 - 02/23/07 04:09 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Apr 2002

Posts: 17,733

Joe

Veteran

|

Veteran

Joined: Apr 2002

Posts: 17,733

Bridgewater, NJ

|

Hello all.

Also you will notice in one of the websites i have posted above in this post that that have the actual ttf (true type font) military spec files you see in the actual F-16. I am going to speak with the higher ups in my company about how much it would cost for me to have panel coated with a black hard anodized coating and the actual military font lettering applied. Do you know what this font is?

|

|

#2145226 - 02/23/07 07:45 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

|

Joined: Mar 2006

Posts: 32

Static

Junior Member

|

Junior Member

Joined: Mar 2006

Posts: 32

Detroit, Michigan

|

Hello again everybody. I will answer a few questions. Joe - http://www.simpits.org/fileproc/showfiles.phpThe AutoCAD Files are on the same page. Search The page for dwg and you will see them. Yes the F-22 file is not very detailed. I can see the F-16 Cockpit in my preview screen in AutoCAD before I try to load it but it wont load up. It just locks. I am using AutoCAD Mechanical Desktop. I wish they put out an IGES file but it is just DWG files. I tried to read them into MasterCAM and it still wont work. MasterCAM has many translators including AutoDesk files. Again Search the page for ttf. http://www.simpits.org/fileproc/showfiles.phpYou will see the ttf files. I use Firefox web browser. Hit CTRL-F and typ in ttf in the blank of the browser at bottom left and keep clicking next till you see it. It is called "F16 Pfont TTF." I should not have said this is the actual milspec ttf as I do not know. I was just over excited to see it. I thought it was. Internet explore also has a search option similar in one of the top menus on the browser. ---------------------------------------------------------------- 453Raafspitty- I do not own any machines. Where I do work we have 14 Verticle CNC Mills. We also have CNC lathes. I do not run lathes. The mills have up to 30 inches of travel I believe but never had to measure them really. I did drill a 2 inch diameter hole about 10 inches deep in some 6061 aluminum about a month ago. I hear routers are the way to go on very thin materials. I have see them in action only once. A little boring for my taste but that is a different type of machining than I am used to. I imagine it is the best application for mass quantity thin parts we are talking about. They usually have very large table area so this makes them usefull for cutting on full sheets with minimal waste and saw cutting time for the stock blanks. -------------------------------------------------------------- To anybody interested- I have nothing at the moment to start cutting. Send me some bezel dimensions or a simple panel for starters. Let me see how involved this gets. Also a nice pic if you can. I need outside dimensions. How big the buttons would be. Overall thickness. I can 3-d cut any contour I see in the pic after drawing it. Screw hole size or the screws to go through. This will be a trial run.

|

|

#2145319 - 02/23/07 09:39 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Mar 2003

Posts: 1,507

Ripcord

Member

|

Member

Joined: Mar 2003

Posts: 1,507

Houston, Texas

|

Static, I will e-mail you the NATOPS for the F/A-18 E/F. It's in PFD format and all you really want are the foldout pages at the back. But those are the only accurate drawings that I know of. Either take them to Kinkos and blow them up 400%, as Pretzel has done, or get somebody to convert them over to AutoCAD or something. I am unable to help with that.

If you have machine time RIGHT NOW going to waste, then run some F-16 bezels. I say that for 2 reasons. First, more pitbuilders to F-16 pits than any other, so they will get gobble up in a snap. And second, more detailed drawing is available. You should have no trouble finding the drawings you need for that over at viperpits.org -- if not, contact somebody there, maybe Kabar03, and ask for help.

But I definately want F/A-18E MFD bezels, and I know others that do as well.

Ripcord

Last edited by Ripcord; 02/23/07 10:05 PM.

USN/USMC -- when it positively, absolutely has to be blown up overnight.

|

|

#2145353 - 02/23/07 10:22 PM

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

Re: CNC Machinist - I can make these parts easy.

[Re: Static]

|

Joined: Apr 2002

Posts: 17,733

Joe

Veteran

|

Veteran

Joined: Apr 2002

Posts: 17,733

Bridgewater, NJ

|

Joe - http://www.simpits.org/fileproc/showfiles.phpThe AutoCAD Files are on the same page. Search The page for dwg and you will see them. Yes the F-22 file is not very detailed. I can see the F-16 Cockpit in my preview screen in AutoCAD before I try to load it but it wont load up. It just locks. I am using AutoCAD Mechanical Desktop. I wish they put out an IGES file but it is just DWG files. I tried to read them into MasterCAM and it still wont work. MasterCAM has many translators including AutoDesk files. Ok, got it. I was looking for something with "F16" in the name. I downloaded it and also cannot open it. I too can see it in the preview window. Something is wrong with the file. I use Firefox web browser. Hit CTRL-F and typ in ttf in the blank of the browser at bottom left and keep clicking next till you see it. It is called "F16 Pfont TTF." I should not have said this is the actual milspec ttf as I do not know. I was just over excited to see it. I thought it was.[/quote]Well, it may be, but we don't know. Someone on another forum asked for the font name, so I thought you might be able to easily provide it. A Firefox tip you might not be aware of - Tools > Options > Advanced. Check the box for "beign finding when you begin typing". No more CTRL+f. The mills have up to 30 inches of travel I believe That's impressive.

I have nothing at the moment to start cutting. Send me some bezel dimensions or a simple panel for starters. Let me see how involved this gets. Also a nice pic if you can. I need outside dimensions. How big the buttons would be. Overall thickness. I can 3-d cut any contour I see in the pic after drawing it. Screw hole size or the screws to go through. This will be a trial run.

You got it. I am printing the NATOPS foldout now at 400% and I'll get you an AutoCAD drawing of the MFD bezel ASAP - at the latest, by the end of the weekend. The MFD bezels are the simplest and the first step in the home cockpit, and you have two guys in this thread that are interested in purchasing them. I'll get you pics, too. Ripcord, I'm going to send you a PM tonight (my time) with links to some of the best pics I've found so far. We can collaborate and send the best one(s) from both of our collections to Static. I will provide a link here or email it to you if you wish; PM with your email address. Do you have an requirements/requests for layers, layer names, or anything else of that sort? Should I be working in inches or millimeters?

|

|

#2145616 - 02/24/07 06:54 AM

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

Re: CNC Machinist - I can make these parts easy.

[Re: Joe]

|

Joined: Mar 2003

Posts: 1,507

Ripcord

Member

|

Member

Joined: Mar 2003

Posts: 1,507

Houston, Texas

|

Joe, thanks for helping him out with the NATOPS to AutoCAD conversion. I appreciate that. Static, I'm in as Joe said, but I am also assuming the price is going to be a range that is reasonable. I suspect it is, but I'd like to ask about that, just to be sure. I have seen F-16 bezels on E-bay (from Jim Keane), but I can't remember now what they sold for -- but they were definately within reason. Would you please give us an idea what you might charge for these? Either post it here or PM one of us. Or I'll e-mail you, actually. Also I'll be travelling this week without a lot of access to the the internet, so don't think I'm disinterested if you don't hear from me for a week or so. Joe, I think the best ones I found were the ones that I posted in that other thread at Frugals. I'll post them again here. http://www.simpits.org/database/RealCockpits/FA18E_1.jpghttp://www.simpits.org/database/RealCockpits/FA18E-2.jpghttp://www.simpits.org/database/RealCockpits/FA18E_3.jpghttp://www.simpits.org/database/RealCockpits/FA18E_4.jpgReally it's just that first one that gives you a good view of the MFD panels. I have one more possibly useful link - these guys actually make and sell these parts for simulators (damn expensive though). http://www.pdt-usa.com/f-18.htmAs you can see, they provide PDF files on each item. Those have some useful info in there, such as dimensions of usable screen area, things like that. cheers, Ripcord

Last edited by Ripcord; 02/24/07 07:25 AM.

USN/USMC -- when it positively, absolutely has to be blown up overnight.

|

|

|

|

|

|

|

|

|

Exodus

by RedOneAlpha. 04/18/24 05:46 PM

|

|

|

|

|

|

|

|

|

|

|

|

|

|